- Dec 9, 2025

UPS Flight 2976 Accident: Reflections on the Left Engine Pylon Failure

- David Lapesa Barrera

On November 4, 2025, UPS Flight 2976, a McDonnell-Douglas (Boeing) MD-11F, was destroyed shortly after takeoff from Louisville Muhammad Ali International Airport, Kentucky. All three crewmembers and eleven people on the ground were fatally injured, and 23 others sustained injuries. During the accident, the left engine and pylon separated from the wing, indicating a critical structural failure.

In response, UPS grounded its MD-11 fleet, and the FAA issued Airworthiness Directive AD 2025-23-51, prohibiting further flight, followed by Emergency AD 2025-23-53, grounding the fleet until approved inspections and corrective actions could be completed.

The aircraft was maintained under a Continuous Airworthiness Maintenance Program (CAMP), the FAA’s system for managing continuing airworthiness, similar in scope to EASA’s CAME. This included an Aircraft Maintenance Program with routine inspections of the left pylon aft mount and lubrication of critical components, such as the pylon thrust links and spherical bearings. Scheduled Special Detailed Inspections (SDIs) for the left pylon aft mount lugs and left wing clevis support were due at a later stage. These inspections may have detected fatigue cracks, in addition to areas susceptible to overstress failure.

Initial Wreckage Evidence

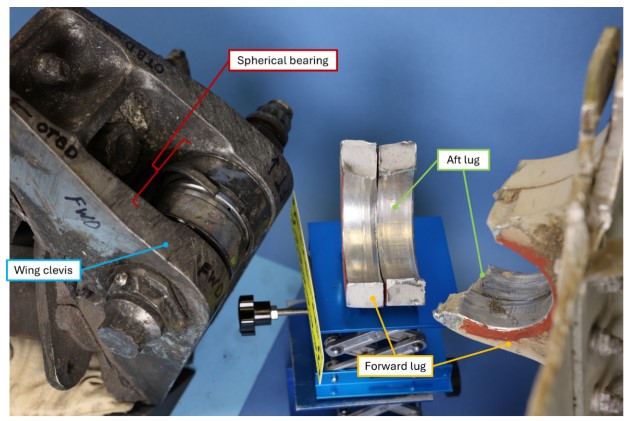

The wreckage was widely scattered and heavily burned. The left engine and pylon were located on and near runway 17R, separated from the aircraft during takeoff. The left pylon’s aft mount forward and aft lugs were fractured, with upper portions adjacent to the runway. The wing clevis, spherical bearing, and associated hardware remained attached to a fragment of the left wing. The spherical bearing’s outer race displayed a circumferential fracture.

The right engine remained attached to its pylon, although both right-side mounts separated from the pylon after impact. This asymmetry reinforced that a failure unique to the left aft mount occurred prior to ground impact.

Materials Laboratory: Fatigue and Overstress

Examination of the left pylon aft mount revealed fatigue cracks in multiple locations:

Aft lug: Fatigue at the boundary where the lug bore meets the forward face.

Forward lug (inboard): Fatigue along the lug bore.

Forward lug (outboard): Overstress failure without fatigue.

Fractured forward and aft lugs, and fractured spherical bearing.

This indicates progressive fatigue culminating in final overload. The forward top flange showed no deformation or pre-existing cracks, suggesting fatigue was localized. The spherical bearing also displayed a circumferential fracture, consistent with overload following degradation.

Aircraft Maintenance Program: MRBR, ALI, and Inspection Intervals

At the time of the accident, the aircraft had 92,992 flight hours and 21,043 flight cycles. The UPS MD-11 Aircraft Maintenance Program incorporated Maintenance Review Board Report (MRBR) tasks and Structural Airworthiness Limitation Items (ALI).

Maintenance Review Board Report (MRBR)

MRBR contains the minimum scheduled maintenance requirements, aiming to maintain inherent safety and reliability while restoring components when deterioration occurs, and minimizing total maintenance and failure costs. It is based on MSG-3 analyses of aircraft systems/powerplants, structures, zonal areas, and L/HIRF. In the UPS case, MRBR included preventive tasks such as:

GVI/DVI of left aft pylon mount (interval: 72 months): Completed October 28, 2021

Lubrication of thrust links and spherical bearings (interval: 24 months / 4,800 flight hours): Completed October 18, 2025

Note: GVI (General Visual Inspection) is a visual check for obvious defects within touching distance to detect damage, failure, or irregularity; DVI (Detailed Visual Inspection) is an intensive inspection to detect less obvious defects; and Lubrication (LUB) is performed to reduce the rate of functional deterioration.

Structural Airworthiness Limitation Items (ALI)

Structural Airworthiness Limitations are mandatory, targeting structures that could contribute to catastrophic failure due to Accidental Damage (AD), Environmental Deterioration (ED) including corrosion or moisture ingress, and Fatigue Damage (FD). These evaluations rely on Damage Tolerance (DT), Fatigue Safe-Life, and Widespread Fatigue Damage (WFD) analyses to define inspections, replacement intervals, or structural modifications. ALIs ensure critical components are inspected or retired before degradation reaches unsafe levels, even if no observable defects are present. The UPS program included:

SDI of Aft mount lugs: Due at 29,200 cycles

SDI of Wing clevis support: Due at 28,000 cycles

Note: Special Detailed Inspection (SDI): Intensive examination to detect defects that require specialized equipment or techniques.

Conclusion

Although the UPS aircraft complied with its approved Aircraft Maintenance Program, including MRBR tasks and ALIs, the preliminary investigation suggests that the inspection intervals for fatigue-critical structure may not have been sufficient to detect developing cracks before catastrophic failure. MRB tasks identify potential failures and maintain general reliability, while ALIs are mandatory safeguards for fatigue-critical or life-limited components, ensuring safety even if no failures are apparent. Further analysis is required to determine all causal and contributing factors.

The UPS Flight 2976 accident demonstrates the critical role of MRBR and ALIs in aircraft structural integrity. Our Aircraft Maintenance Programs course equips aviation professionals with the knowledge to fully understand these programs and how they guide real-world maintenance practices.