- Mar 6, 2025

MSG-3 Analysis (Part I): All Systems Go - Powerplants Included!

- David Lapesa Barrera

MSG-3 analysis isn’t just about defining maintenance tasks—it shapes key Aircraft Maintenance Program procedures, from initial scheduling to task escalation and how maintenance history is transferred with components. Read to the end!

The Systems and Powerplant Analysis Procedure is a crucial part of the MSG-3 methodology for determining the optimal maintenance strategies for aircraft systems and powerplants.

Here's how the process unfolds:

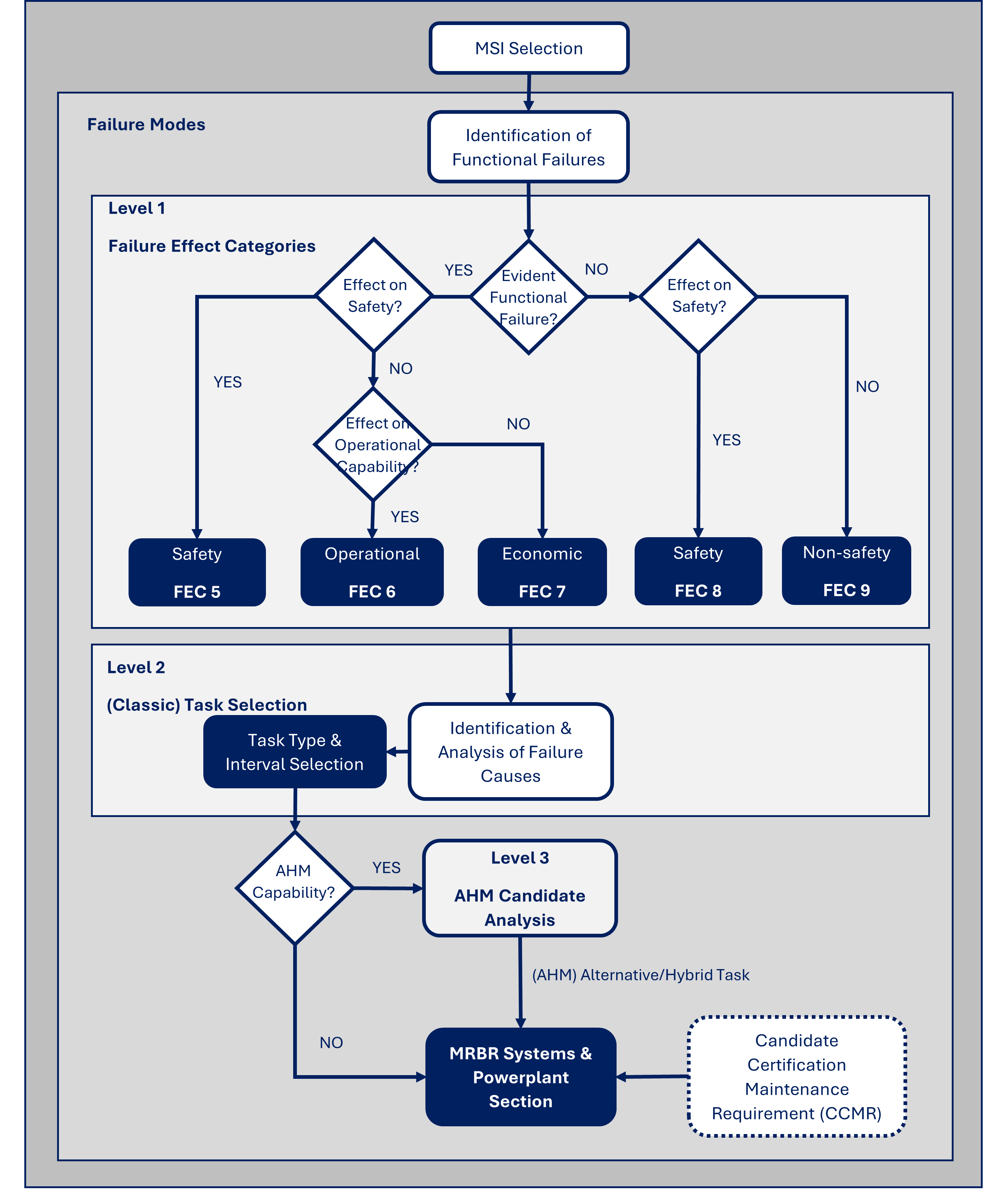

Simplified MSG-3 Analysis for Systems and Powerplants. Source: Aircraft Maintenance Programs (Lapesa Barrera, 2022).

Step 1: Identifying Maintenance Significant Items (MSIs)

The first step in the process is to identify Maintenance Significant Items (MSIs) through a top-down approach. This process classifies the aircraft's major functional areas, ATA systems, subsystems, and individual replaceable items, down to the smallest level. The highest manageable level of items subject to failure—those that could impact safety, operational performance, or economic factors—is selected for the "Candidate MSI List." The list is then reviewed by the Industry Steering Committee (ISC) and validated by the Working Groups.

Once the MSIs are identified, the following are analyzed for each MSI:

Function: The normal operational characteristics of the item.

Functional Failures: The failure of the item to perform its intended function.

Failure Effects: The consequences resulting from the functional failures.

Failure Causes: The underlying reasons behind the failures.

Step 2: Categorizing Failure Effects (Level 1 Analysis)

In MSG-3, failure effects are classified into "Failure Effect Categories" (FECs), helping prioritize the maintenance tasks needed:

Evident Safety (FEC 5): Tasks required to ensure the safe operation of the aircraft.

Evident Operational (FEC 6): Tasks that help reduce the risk of failure but are not immediately required.

Evident Economic (FEC 7): Tasks that are desirable if they are less costly than the repair costs.

Hidden Safety (FEC 8): Tasks that are required to prevent safety issues that might not be immediately detectable by the crew.

Hidden Non-safety (FEC 9): Tasks that reduce the economic effects of failure that are not immediately evident.

In this system, “evident” or “hidden” refers to whether or not the crew can detect the failure during normal operations.

Step 3: Selecting Appropriate Maintenance Tasks (Level 2 Analysis)

Lubrication (LUB) / Servicing (SVC) (All FEC categories):

The purpose is to slow down wear by replenishing consumables to maintain inherent design capabilities. This task is selected when replenishing consumables reduces the rate of functional deterioration.Operational (OPC) / Visual Check (VCK) (FEC 8 & 9):

The purpose is to confirm that an item is fulfilling its intended purpose without requiring quantitative tolerances; it is a failure-finding task. This task is selected when it is possible to identify the failure through a visual check or operational performance.-

Inspection (GVI / DET / SDI) / Functional Check (FNC) (All FEC categories):

The purpose of an inspection is to detect damage, failure, or irregularity, while the purpose of a functional check is to determine if the function(s) of an item perform within specified limits. This task is selected when the reduced resistance to failure is detectable, and there exists a consistent interval between deterioration condition and functional failure. The inspection types are:General Visual Inspection (GVI): Quick visual check for obvious defects within touching distance.

Detailed Visual Inspection (DET): Intensive examination to detect defects.

Special Detailed Inspection (SDI): Intensive examination using specialized equipment/techniques.

Restoration (RST) (All FEC categories):

The purpose is to return the item to a specific standard. This task is selected when the item shows functional degradation at a certain point in its life, and most of the units are expected to be used after that point.Discard (DIS) (All FEC categories):

The purpose is to remove the item from service at a specified life limit. This task is selected when the item shows functional degradation at a certain point in its life, and most units are expected to be used after that point, but it is not possible to restore the item to a specific standard.Combination Tasks (FEC 5 & 8):

For the safety categories, it is necessary to analyze all possibilities to choose the most effective task(s). This is used for critical safety-related failures to ensure the most effective approach.

Note: Level 3 Analysis now allows the integration of Aircraft Health Monitoring (AHM), extending MSG-3 beyond classic task selection. For details, see our article on AHM.

Note: Certification Maintenance Requirements (CMR) come from a different analysis than MSG-3: the System Safety Analysis. If an MSG-3 task is safety-categorized, meets the Candidate CMR’s interval and scope, and is approved by the Industry Steering Committee, it can replace a Candidate CMR.

Step 4: Task Intervals and Maintenance Scheduling

Maintenance Working Groups (MWG) define task intervals based on data, failure rates, operational experience, and the recommendations of manufacturers and customers. During this process, appropriate parameter(s) - flight hours, flight cycles, calendar time, engine/APU hours/cycles, engine/landing gear change, etc. - and the associated numerical interval(s) are identified.

Note: Tasks should not be scheduled more frequently than necessary, as excessive maintenance could lead to adverse effects on safety and reliability.

Sampling for In-Service Deterioration

When no enough experience to determine appropriate tasks and intervals exist, the MSG-3 methodology can implement Sampling programs to examine certain number of items that are subject to in-service deterioration. No-sampled items continue in service until the results of the Sampling determine the need for additional tasks and/or item improvement.

FEC Categorization in AMP Procedures

Considering FEC categorization is critical in several key procedures of an Aircraft Maintenance Program (AMP), including:

Clock Starting Point & Grace Periods: FEC ensures critical tasks are quickly identified, maintaining aircraft safety with timely maintenance and minimal grace periods.

Robbery Procedures (Component Transfer between Aircraft): FEC categorization helps determine if maintenance history should be transferred when parts are moved between aircraft, especially when not defined at the component level. This ensures continued safety and reliability. (Remember, MSG-3 focuses on systems, not components—though there are exceptions.)

Task Effectiveness & Task Escalation: Safety-related tasks in FEC categories 5 and 8 may need escalation, but this can happen without changing the content of the AMP.

Operators must consider FEC categorization when prioritizing tasks to ensure timely maintenance, proper transfer of maintenance history, the correct escalation of safety tasks, and effective AMP task analysis. This approach ensures safety, efficiency, and long-term operational success.

Conclusion

The structured approach, from identifying MSIs to selecting the right tasks and intervals, is a proven method. The Systems and Powerplant Analysis Procedure in MSG-3 ensures that aircraft systems are maintained effectively, keeping both safety and operational efficiency in focus.

Curious to learn more about MSG-3?

Explore more articles on The Lean Airworthiness Blog or advance your skills with our Aircraft Maintenance Programs (Specialist Level) course.