- Mar 11, 2025

MSG-3 Analysis (Part II): Preventing Structural Deterioration

- David Lapesa Barrera

MSG-3 for aircraft structures focuses on identifying maintenance tasks that prevent structural deterioration and ensure continued safety and reliability. This applies to the fuselage, empennage, engine mountings, landing gear, flight control surfaces, and related attachment points.

Here’s how:

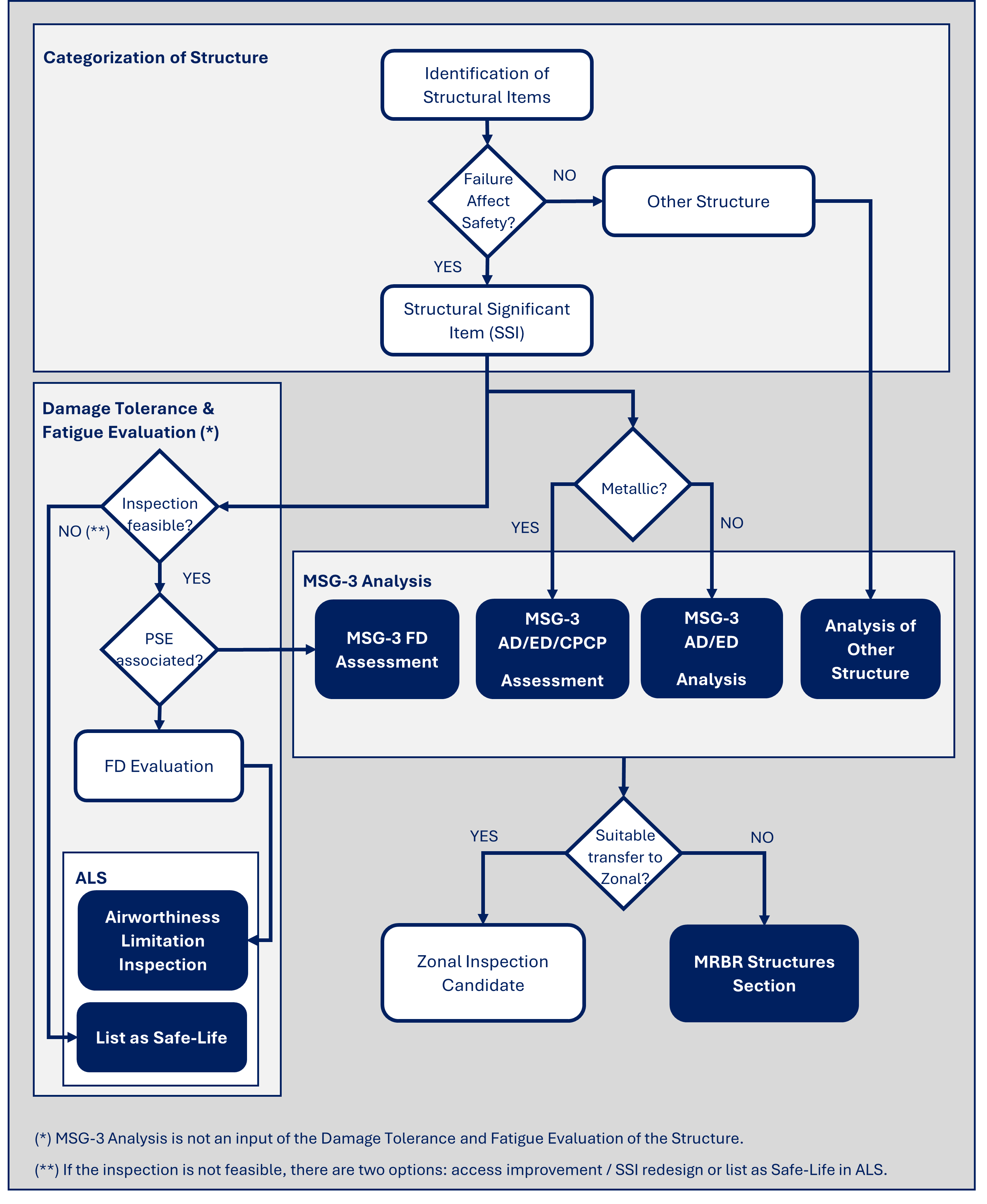

Simplified MSG-3 Analysis for Aircraft Structures. Source: Aircraft Maintenance Programs (Lapesa Barrera, 2022).

Step 1: Categorizing Structural Components

The MSG-3 process begins with identifying and categorizing the components of the aircraft structure:

Structural Significant Items (SSIs): any item that in case of failure could affect the structural integrity necessary for the safe operation of the aircraft.

Other Structure: any other structural item not classified as SSI.

Note: A Principal Structural Element (PSE) is an element that contributes significantly to the carrying of flight, ground, or pressurization loads, and whose integrity is essential in maintaining the overall structural integrity of the aircraft. SSIs associated PSE undergo a more detailed Damage Tolerance and Fatigue Evaluation as part of certification. The Structural Airworthiness Limitations are the result of such different process.

Step 2: Identifying Damage Sources

Once the structural items are categorized, the next step is to identify the potential sources of damage, which are typically grouped into three categories:

Accidental Damage (AD): random event which may reduce the strength of the structure and is not readily detectable. For example, handling equipment, foreign objects, hail, lighting, runway debris, etc. Large-size ADs as a bird strike, large hail, or major collisions that are detectable immediately are not part of this assessment.

Environmental Deterioration (ED): deterioration as a result of chemical interaction with the climate or environment. For example, corrosion and stress corrosion cracking, which is the combination of a corrosive environment and tensile stress. Corrosion Prevention and Control Programs (CPCP) are designed to control an aircraft structure to Corrosion Level 1 or better, meaning that the corrosion damage does not require structural reinforcement or replacement.

Fatigue Damage (FD): propagation of cyclic loading of cracks. Regular inspections are necessary to identify early signs of fatigue damage, preventing failure.

Step 3: Defining Maintenance Tasks

For SSIs not associated with PSEs, the analysis focuses on detecting potential failures and selecting appropriate maintenance tasks:

Damage Tolerance (DT) Evaluation: Determines whether a structure can sustain damage without immediate failure until detected. The manufacturer establishes whether timely detection depends on scheduled inspections.

-

Material-Based Analysis:

Metallic Structures: Inspection requirements are established for AD, ED, and CPCP. If ED and CPCP requirements are similar, the ED task covers both; otherwise, a separate CPCP task is defined.

Non-Metallic Structures: Inspection requirements for AD and ED are established, considering how AD affects ED detection.

For Other Structure, if the item has similar items on existing aircraft, the Structures Working Group (SWG) will develop the maintenance recommendations; otherwise, e.g., for new materials or designs, the recommendations will be given by the manufacturer.

Step 4: Transfer to Zonal Inspections

Tasks from FD, AD, ED/CPCP (other than Airworthiness Limitations), and tasks from the Other Structure analysis are evaluated for zonal transfer and either become zonal inspection candidates or are listed in the MRBR Structures Section.

Conclusion

The MSG-3 methodology ensures that aircraft structures remain operational and safe over time by categorizing critical components, identifying potential sources of damage, defining appropriate maintenance tasks, and scheduling inspections. By focusing on Structural Significant Items (SSIs) and conducting thorough inspections for Accidental Damage, Environmental Deterioration, and Fatigue Damage, the process minimizes risks and contributes to Continuing Airworthiness.

Want to keep learning?

Subscribe to The Lean Airworthiness Blog for more insights on aircraft maintenance, or take the next step with our Aircraft Maintenance Programs (Specialist) course to deepen your expertise and get certified.