- Mar 18, 2025

MSG-3 Analysis (Part III): No Zone Left Behind!

- David Lapesa Barrera

Zonal inspections are a crucial part of the MSG-3 methodology, focusing on ensuring aircraft safety and reliability. These inspections are designed to identify potential risks in each zone, particularly within Electrical Wiring Interconnection Systems (EWIS), which have been linked to past aircraft accidents.

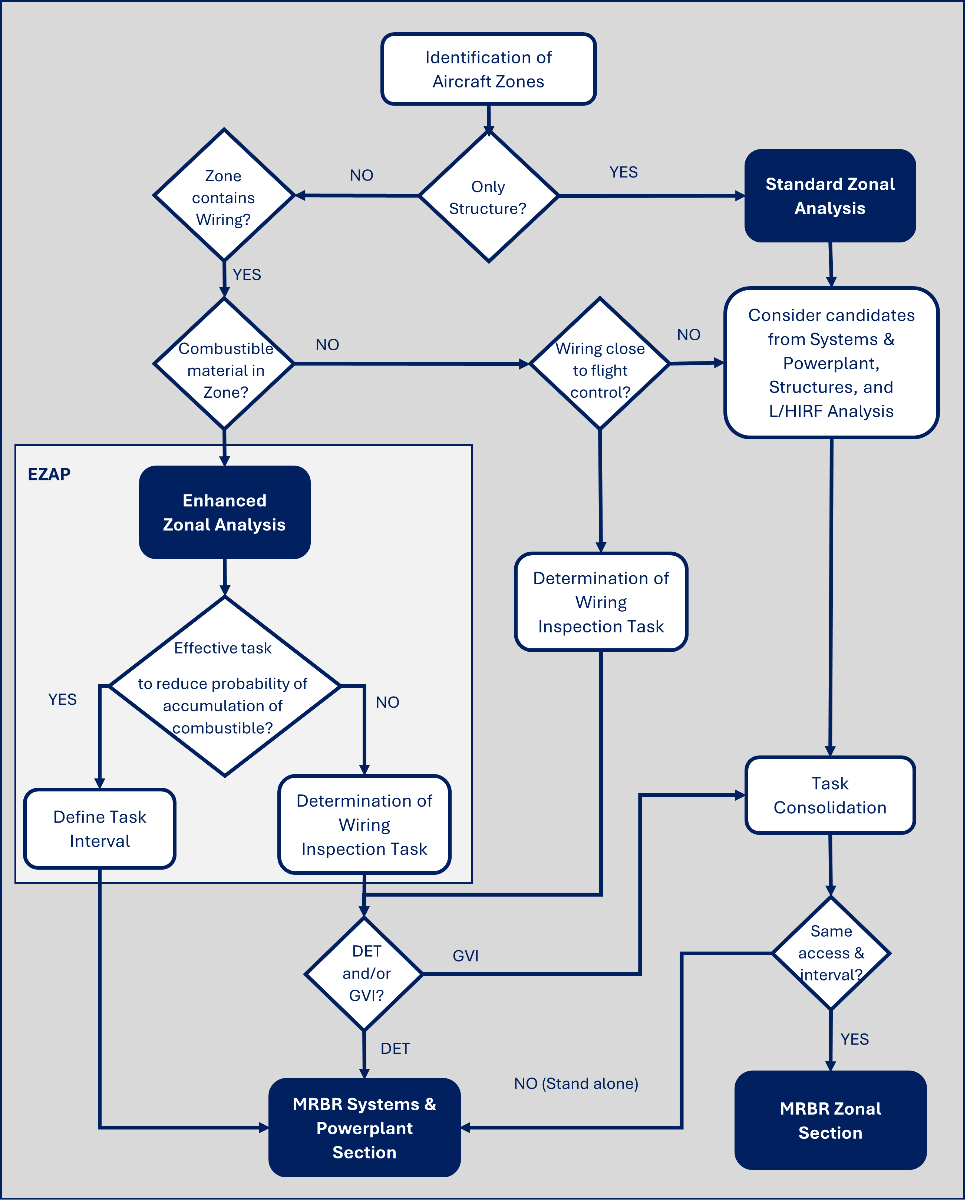

Here's a step-by-step breakdown of the MSG-3 Zonal Analysis process.

Simplified MSG-3 Zonal Analysis. Source: Aircraft Maintenance Programs (Lapesa Barrera, 2022).

Step 1: Divide the Aircraft into Zones

The first step in the MSG-3 process is dividing the aircraft into zones, as outlined in the ATA iSpec 2200. Each zone must be reviewed with its corresponding:

Access: Evaluating how easily a zone can be accessed for inspections.

Installed Equipment: Identifying the equipment in each zone that could impact the inspection tasks.

L/HIRF Protection: Details of protection from lightning and high-intensity radiated fields.

Wire Bundle Installation: Checking which and how wiring is installed.

Combustible Materials: Assessing the potential presence of any combustible materials within the zone.

Step 2: Choose the Type of Zonal Analysis and Select Appropriate Inspection Tasks

There are two main types of zonal analysis, depending on the zone's complexity:

-

Standard Zonal Analysis: Applied to zones that contain only structural components or systems installations, without electrical wiring. All tasks developed through the standard zonal analysis should be included in the Zonal Inspections. However, these may be compared with the GVIs (General Visual Inspections) arisen from the Systems and Powerplant, Structures, and L/HIRF analysis procedures in this way:

If the access requirement is the same and the proposed interval is at least as frequent, the Zonal Inspection will fully cover the GVI.

Otherwise, a stand-alone GVI should be included in the corresponding MSI for Systems and Powerplant, in the SSI for structures, and LHSI for L/HIRF, from which it was identified.

-

Enhanced Zonal Analysis Procedure (EZAP): for zones that contain systems installations with electrical wiring, including potential for combustible material presence. The EZAP identifies stand-alone inspection tasks focused on EWIS. Task type selection:

-

GVIs (General Visual Inspections) may be found effective for the complete zone. GVIs arising from the EZAP are to be compared with the Zonal Inspections result of the standard zonal analysis.I

If the access requirement is the same and the proposed interval is at least as frequent, the Zonal Inspection will fully cover the GVI.

Otherwise, a stand-alone GVI should be included in the Systems and Powerplant tasks under ATA 20 Standards Practices—Airframe with references to the EZAP.

DETs (Detailed Inspections) may be found effective for specific items in a zone. A DET is a more intensive examination of a specific item, installation or assembly to detect damage, failure or irregularity In this case, it should be included in the Systems and Powerplant tasks under ATA 20 Standards Practices—Airframe with references to the EZAP.

-

Whenever possible, the intervals should match those selected for targeted schedule maintenance checks.

Identify Potential Risks and Focus Areas

During zonal inspections, special attention is given to the following:

EWIS: After past accidents linked to electrical wiring degradation, special focus is placed on EWIS, including all electrical connections and terminals that transmit energy or data. Ensuring these systems are in good condition is vital for aircraft safety.

Combustible Materials: Potential riks derived from the presence of combustible material, either through contamination (e.g., dust and lint) or occurring by design (e.g., fuel vapor).

Conclusion

By following these steps, the MSG-3 methodology ensures that every aircraft zone is inspected and maintained properly to uphold safety standards. Zonal inspections help identify potential issues before they become critical, particularly in electrical systems, contributing to ongoing airworthiness.

Want to keep learning?

Subscribe to The Lean Airworthiness Blog for more insights on MSG-3 and aircraft maintenance, or take the next step with our Aircraft Maintenance Programs (Specialist Level) course to deepen your expertise and get certified.