- Feb 25, 2025

Critical Maintenance Task Matrix Reloaded (Part II): Redefining Safety

- David Lapesa Barrera

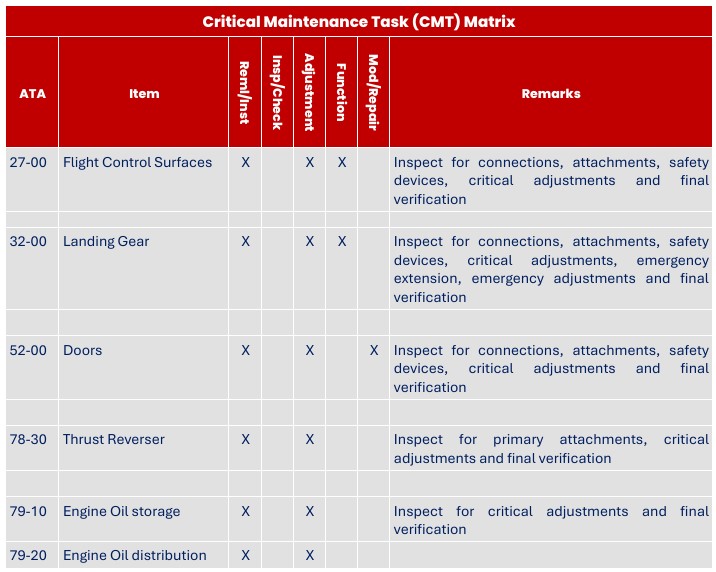

In the previous post, Enter the Matrix: Decoding Critical Maintenance Tasks (Part I), we took the 🔴 red pill and introduced the Critical Maintenance Task (CMT) Matrix and how it serves as a vital tool for ensuring flight safety by standardizing the identification of tasks that require error-capturing methods. By using the matrix, we can categorize tasks, prioritize safety-critical functions, and standardize maintenance processes, all of which ultimately contribute to reducing risk.

A Critical Maintenance Task (CMT) is any task involving the assembly or disturbance of a system or component in an aircraft where an error could directly jeopardize flight safety.

Now, let’s dive deeper into how to develop and implement the CMT Matrix in your organization, leveraging regulatory requirements, information from the design approval holder, historical data, and continuous improvement practices.

Critical Maintenance Task (CMT) Matrix example

1. Regulations

The foundation of a well-structured CMT Matrix begins with a solid understanding of regulations. Aviation regulatory bodies such as the European Union Aviation Safety Agency (EASA), the Federal Aviation Administration (FAA), and other civil aviation authorities provide crucial guidelines that shape maintenance practices and safety protocols.

Continuing Airworthiness regulations provide a starting point for your CMT Matrix. By assessing these guidelines, you will be able to identify which tasks require mandatory error-capturing methods and establish a framework for defining the critical nature of maintenance task instructions.

2. Task Classification

Task classification is the next critical step in the development of your CMT Matrix. To categorize maintenance tasks accurately, refer to multiple sources, including:

Airworthiness Directives (ADs)

Airworthiness Limitations Sections (ALS)

Maintenance Review Board Reports (MRBR) and Failure Effect Category (FEC) Classification

Service Bulletins (SBs)

OEM Manuals

Each of these sources plays a crucial role in identifying tasks that directly impact the aircraft’s safety and operation. While safety-related tasks are inherently critical, the criticality of maintenance refers to the importance of performing the task without error. Even tasks that are not directly safety-related can still be critical in maintenance due to their potential to indirectly impact aircraft systems necessary for safe operation.

We recommend considering all tasks as critical unless proven otherwise through the classification process that follows. In aviation, all maintenance tasks should initially be treated as critical due to the high safety standards. Only through a detailed assessment process can tasks be identified as non-critical, based on a clear understanding of their potential risks and impact on safety.

Tasks with severe safety impacts, such as those affecting critical flight controls, are more likely to be classified as CMTs. Identifying CMTs requires a comprehensive assessment, taking into account both the safety risk and the operational context.

3. In-Service Experience and Reliability Data

In-service experience is essential for refining CMT identification. By analyzing historical reliability data, organizations can pinpoint tasks that frequently lead to operational disruptions or safety concerns. This data can help classify tasks as CMTs, especially when the potential risk of failure directly jeopardizes flight safety.

This historical data helps organizations proactively identify critical tasks that may not be immediately obvious from regulatory or manufacturer guidelines alone.

4. Additional Sources for Task Identification

Several other sources can aid in identifying CMTs:

Information from the design approval holder or compliance declarations.

Accident reports and investigations.

Occurrence reporting and incident follow-ups.

Flight data analysis.

Audit results.

Normal operations monitoring.

Feedback from training.

Information exchange systems.

By integrating these and other relevant sources, organizations ensure a comprehensive approach to identifying critical maintenance tasks.

5. Safety Risk Matrix

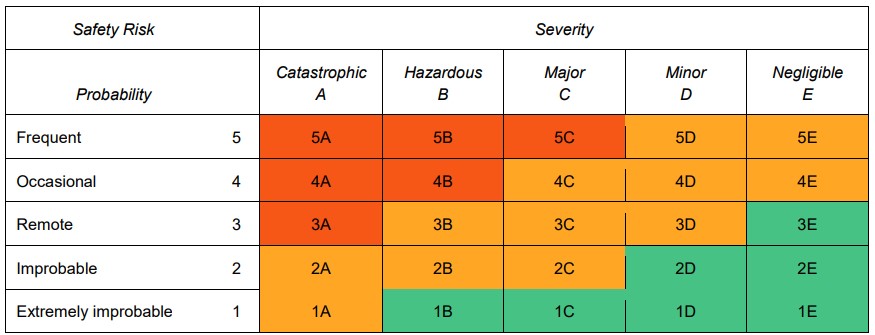

Tasks that are not immediately identified as CMTs can continue through a structured risk assessment. One of the most effective tools for identifying and categorizing critical maintenance is the Safety Risk Matrix. In the context of CMT identification, this matrix helps assess the potential risk associated with the incorrect accomplishment of a maintenance task by evaluating both the likelihood of a maintenance error and the severity of its consequences on safety and operations.

A task with a high probability of error but low severity may still require increased oversight, while a low-probability, high-severity task may necessitate robust error-capturing methods to mitigate potential risks effectively.

(ICAO Doc 9859: Safety Management Manual (SMM) - Safety Risk Matrix)

By applying the Safety Risk Matrix, organizations can prioritize CMTs based on risk, ensuring that the most safety-critical tasks receive the necessary attention, including independent inspections or re-inspections.

(Safety Risk Matrix also has broader applications in aviation risk management, including hazard assessment, incident analysis, and overall safety decision-making.)

5. Collaborating Across Expertise and Stakeholders

Developing an effective CMT Matrix requires collaboration across different teams within the organization. Continuing airworthiness teams, maintenance teams, safety officers, and compliance experts should all contribute to ensure the matrix reflects both practical realities and necessary safety standards.

Brainstorming sessions can be an excellent way to bring these stakeholders together. By sharing insights and knowledge, each team can help identify potential risks and prioritize the tasks that require error-capturing methods. This collaboration ensures the CMT Matrix is comprehensive and effective, balancing regulatory requirements with practical, real-world experience.

Through these collaborative efforts, the CMT Matrix becomes not just a static tool but a shared, living document. It must continuously evolve, integrating new insights, data, and feedback from the teams working on the ground to stay relevant and effective.

6. Continuous Improvement Process: Building a Stronger CMT Matrix

Developing a CMT Matrix is an ongoing process, and the key to its success lies in continuous improvement. To build a more effective matrix:

Train your teams: Ensure that your maintenance teams are trained to identify and apply the matrix effectively. Training ensures consistency and helps prevent errors in the identification process.

Review and update: The matrix should be reviewed regularly to account for new risks, regulations, and operational changes. This review process is critical in adapting to evolving technologies, safety standards, and operational realities.

Feedback loops: Incorporating feedback from your maintenance teams, training programs, and audits is essential for refining the matrix. Continuous feedback helps adapt the matrix to real-world conditions and ensures its effectiveness in preventing errors.

By establishing these practices, your organization can ensure that the CMT Matrix remains a dynamic and robust tool for improving flight safety.

Conclusion

The CMT Matrix is a crucial tool for identifying and managing Critical Maintenance Tasks, ensuring flight safety, and reducing risks. Keep in mind that each organization should develop its own matrix based on specific needs. We hope our two articles on this topic serve as a good starting point.

Take the Next Step:

Aircraft Maintenance Programs (Advanced Expert)

Gain hands-on expertise in identifying and managing Critical Maintenance Tasks, applying error-capturing methods, and implementing a robust CMT Matrix within your organization. Develop practical skills to improve flight safety, maintenance reliability, and operational efficiency.