- Feb 18, 2025

Enter the Matrix (Part I): Decoding Critical Maintenance Tasks

- David Lapesa Barrera

We can define what a Critical Maintenance Task (CMT) is, explain its significance for flight Safety and Reliability, and outline the error-capturing methods designed to prevent mistakes. But let’s be honest - what you really want to know is:

How do you identify them?

Regulatory guidance provides a framework, but it also allows for flexibility in implementation—sometimes so much that organizations struggle to apply it consistently. The result? Inconsistent application, hidden risks, and potential compliance gaps.

Now is your time. You can take the 🔵 blue pill, continue discussing CMTs in endless circles, forget everything, and return to your normal work. Or, you can take the 🔴 red pill, uncover the truth, and dive straight into how to identify critical tasks within the Matrix. The choice is yours.

If you choose the red pill, let’s dive in!

What Are Critical Maintenance Tasks (CMTs)?

These are tasks that involve the assembly or disturbance of an aircraft, engine, or propeller system, where an error could directly compromise flight safety.

To mitigate risks, regulations require an error-capturing method to detect maintenance errors or omissions. There are two primary methods:

Independent Inspection – Conducted by an independent, qualified person to verify that the task was completed correctly and without deficiencies by the authorized person responsible for the work.

-

Re-inspection – Used in unforeseen situations where only one person is available, requiring the same authorized person to inspect their own work before releasing the aircraft.

How Are Critical Maintenance Tasks Identified?

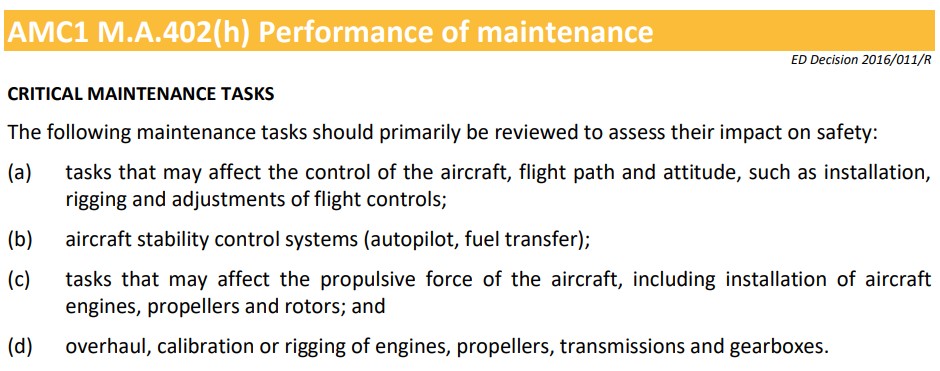

Let’s take EASA AMC1 M.A.402(h) Performance of Maintenance as a reference. It highlights key maintenance tasks that should be reviewed for criticality, and that’s where the guidance starts and ends.

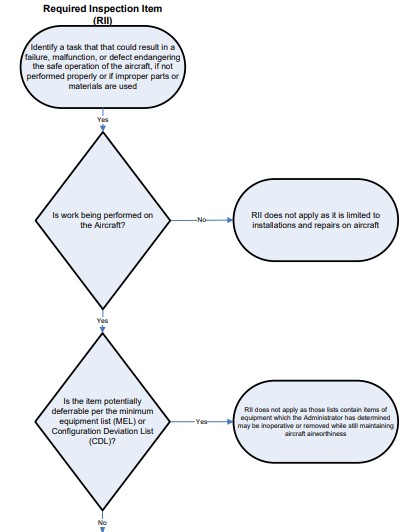

The FAA AC 120-16G provides a clearer method for identifying critical maintenance tasks, though they use the term "Required Inspection Item" (RII) instead of CMT. To help with this, the Advisory Circular includes a simple decision logic diagram that guides operators in determining which tasks require special inspection.

Is Regulatory Guidance Enough to Standardize Identification?

Each organization is unique, with its own challenges and processes. While flexibility can be beneficial—allowing operators and maintenance organizations to tailor their approach—it also creates inconsistencies in how CMTs are identified and controlled.

For scheduled maintenance, the job can typically be planned and identified in advance, allowing for a more structured and predictable approach to identifying CMTs. However, for unscheduled maintenance, particularly in unforeseen circumstances, there is a greater need for a tool or framework that enables quicker, more efficient identification of critical tasks under time pressure.

Without a clear method for identification, maintenance teams may:

❌ Miss high-risk tasks because they aren’t clearly identified as “critical.”, and

❌ Apply inspection methods incorrectly, which could lead to potential compliance gaps or safety risks.

Do you agree?

The Lean Approach: The Critical Maintenance Task Matrix

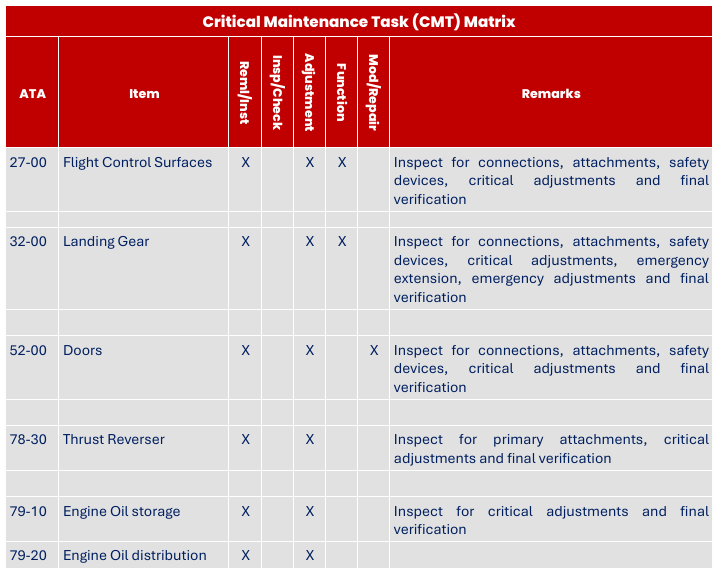

The Critical Maintenance Task (CMT) Matrix is a tool that helps organizations identify which tasks require error-capturing methods, such as Independent Inspection or Re-inspection, to ensure their accomplishment don't endanger flight safety. This matrix categorizes maintenance tasks based on several key factors, ensuring the right checks are in place to mitigate risk.

Critical Maintenance Task (CMT) Matrix example

Key Components of the Matrix:

1. Task Type – The matrix categorizes tasks into different types based on their nature:

Installation: Tasks involving the installation of components or systems that are critical to flight safety.

Adjustment: Tasks where components or systems are adjusted or fine-tuned for correct operation.

Functional Test: Tasks that test systems or components to ensure they function properly.

Overhaul: Tasks involving significant disassembly and reassembly of components or systems.

Calibration: Tasks ensuring that components or systems are correctly calibrated to manufacturer specifications.

Major Repair and Alteration: Tasks involving significant repairs or alterations, typically affecting multiple system elements.

2. ATA Chapter and Subchapter – The matrix also links each task to the relevant ATA chapters and subchapters. These chapters are structured to ensure specific maintenance tasks are addressed by their correct categories, allowing for better management of critical tasks. For example, ATA Chapter 27 – Flight control systems require inspection to ensure proper assembly, lock mechanisms, and functional checks, ensuring no errors compromise control during flight.

3. Error-Capturing Inspection Focus – It’s important to highlight that Error-capturing methods are focused on the critical aspects of the task, not every minor step. For example, for adjustments, the inspection focuses on whether the system was tuned properly, but it may not recheck every single adjustment made in the process.

By using a structured CMT Matrix, maintenance organizations can remove guesswork, standardize error-prevention processes, and improve both safety and efficiency. It also makes it easier to identify critical tasks quickly, which is especially important during unscheduled maintenance when resources may be limited.

Developing and Applying Your Own CMT Matrix

Remember, the CMT Matrix is a framework for your organization to build upon. In the next post, we’ll walk you through the process of developing your own CMT Matrix and demonstrate how to apply it effectively within your organization.

Next Steps:

Gain hands-on expertise in CMT identification, error-prevention methods, and applied Airworthiness concepts with our Aircraft Maintenance Programs courses. Learn to tackle real-world maintenance challenges and strengthen your professional skills.