- Dec 16, 2025

The Reliability Cycle: A Continuous Approach to Aircraft Reliability

- David Lapesa Barrera

Every aircraft is designed with an inherent reliability—the expected ability of its systems and components to perform safely and efficiently under normal operating conditions. However, inherent reliability alone cannot guarantee safe, uninterrupted operations. Factors such as operational conditions, maintenance practices, and unexpected wear can affect system performance over time.

To manage these variables effectively, operators rely on Reliability Programs that monitor performance, detect deviations, implement corrective actions, and track the results (the Reliability Cycle). Regulatory authorities also expect that Aircraft Maintenance Programs (AMPs) developed using MSG-3 methodology are accompanied by a Reliability Program, ensuring that scheduled maintenance tasks are supported by continuous monitoring and performance verification.

Objectives of an Aircraft Maintenance Program (AMP)

An effective AMP provides a systematic framework to preserve and enhance the inherent reliability of aircraft systems. Its objectives include:

Ensure the aircraft’s safety and reliability perform at their designed levels.

Restore safety and reliability when they have deteriorated.

Gather information to improve the design of components whose inherent reliability proves inadequate. If reliability is found to be unsatisfactory, design modifications may be required.

Achieve these goals at the lowest possible total cost, including maintenance and failure costs.

Objectives of a Reliability Program

While the AMP focuses on scheduled maintenance, a Reliability Program ensures comprehensive oversight:

Ensure the effectiveness of the AMP – By monitoring scheduled tasks, the program verifies that the AMP achieves its intended safety and reliability goals.

Monitor unscheduled items – It also tracks components and systems without scheduled tasks, identifying potential reliability issues and maintaining overall aircraft performance.

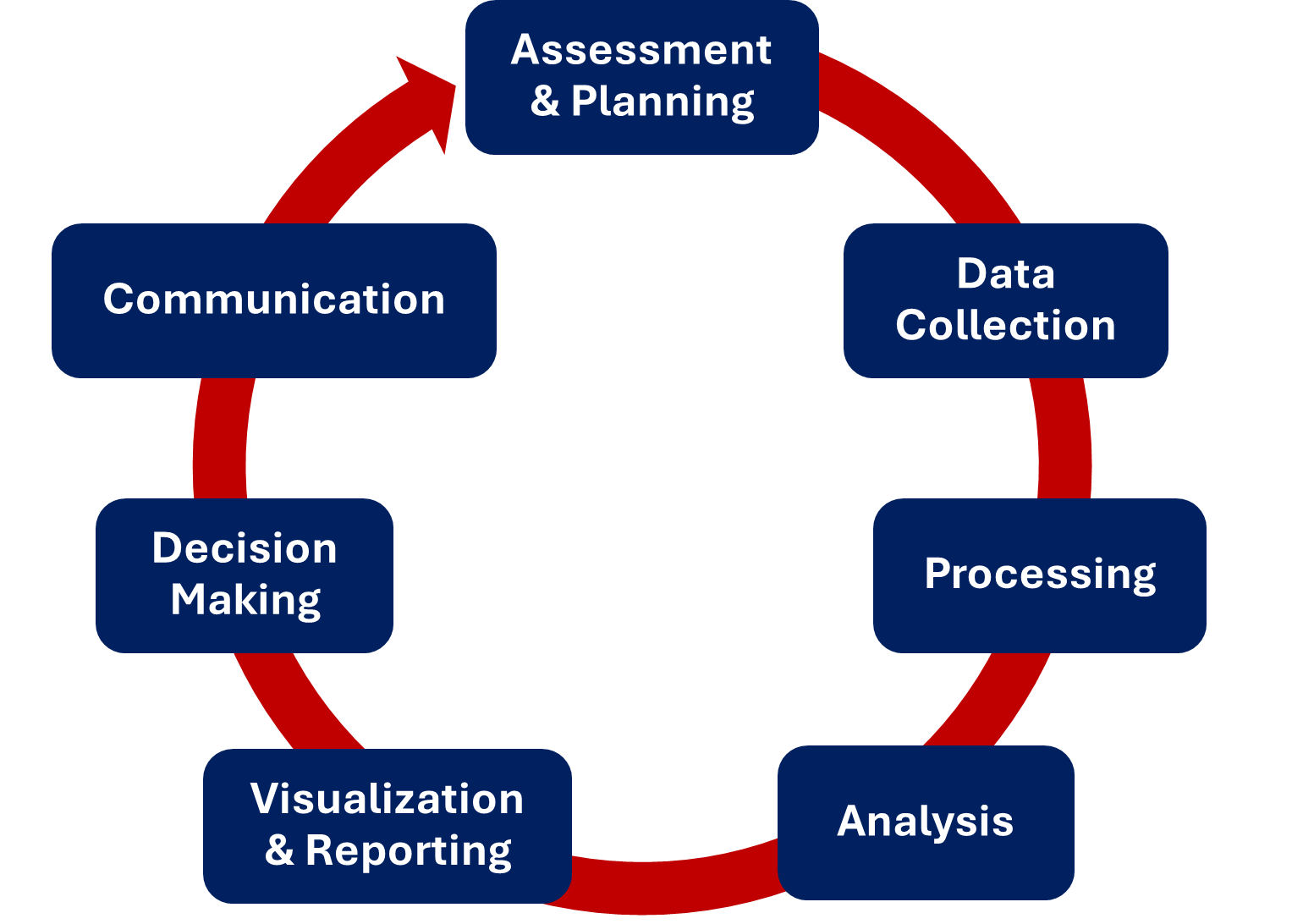

The Reliability Cycle

At the heart of every effective Reliability Program is the Reliability Cycle, a systematic, iterative sequence of steps that drives continuous improvement:

1. Assessment and Planning

Operators identify which systems and components require monitoring and define performance standards, including alert thresholds. This step sets the program’s scope, ensuring resources are focused on areas with the greatest impact on safety and performance. Planning also incorporates regulatory requirements, operational context, and stakeholder goals.

2. Data Collection

High-quality data is gathered from flight logs, maintenance records, operational reports, and aircraft monitoring systems. Comprehensive data collection allows early detection of anomalies and performance degradation.

3. Data Processing

Collected data is validated and organized to ensure accuracy and relevance. Deviations from performance standards are highlighted, enabling early identification of potential reliability issues.

4. Analysis

Engineers examine processed data to determine root causes, identify recurring patterns, and understand failure mechanisms. The effectiveness of existing AMP tasks is also evaluated, ensuring that recommended actions focus on areas needing improvement. Preventive maintenance, operational procedure updates, or design enhancements may be proposed and assessed for safety, operational benefit, and cost-effectiveness.

5. Visualization and Reporting

Analysis results are communicated through dashboards, charts, and Reliability Reports that clearly present trends and key performance indicators, enabling data-informed decision-making.

6. Review and Decision-Making

Stakeholders—including engineers, maintenance leaders, and management—review reports and recommendations. Decisions are guided by data but informed by professional experience and engineering judgment, ensuring interventions are justified and aligned with organizational objectives.

7. Implementation

Decisions are executed by maintenance teams, engineers, and operational staff, turning insights into tangible improvements in aircraft reliability.

Continuous Improvement

Because the Reliability Cycle is iterative, each loop strengthens understanding of system performance. Insights from one cycle refine performance standards, maintenance tasks, and monitoring strategies, creating a continuous improvement loop that enhances reliability over time. When the cycle is not monitored or applied iteratively, reliability issues can go undetected, maintenance efforts may be inefficient, and operational performance can suffer.

Conclusion

The Reliability Cycle is essential for safe, efficient, and cost-effective aircraft operations. By systematically monitoring performance, analyzing deviations, and applying corrective actions, operators can preserve inherent aircraft reliability, ensure compliance, and continuously improve system performance.

Want to master the Reliability Cycle and learn how to implement a comprehensive Reliability Program?

Explore our Reliability Programs Course and discover how to effectively monitor, analyze, and improve system performance across your fleet.