- Oct 10, 2024

PDCA Cycle: A First-Class Upgrade for Your Processes!

- David Lapesa Barrera

Who is better equipped to document and improve processes than the very people currently executing the job? Their insights and experiences are invaluable in crafting effective practices that drive operational excellence.

What is Standardized Work?

Standardized work is about documenting and establishing best practices for every task, ensuring that we eliminate variability, reduce waste, improve quality, and boost efficiency. But where does this transformation take place? At the Gemba - the Japanese term for the actual location where work is done.

By engaging with employees and observing their day-to-day activities, organizations gain invaluable insights. This hands-on approach allows us to craft practical, effective standardized work procedures. Once we’ve identified the most efficient ways to operate, we document these practices and provide comprehensive training to ensure everyone is on the same page. This promotes uniformity and reliability across teams, creating a seamless operational experience.

A Strong Foundation for Continuous Improvement

Standardized work isn’t just about instructions; it’s about building a culture of excellence. It includes detailed procedures and guidelines that outline the exact steps to follow, supported by Key Performance Indicators (KPIs) to monitor performance.

Utilizing tools like Business Process Mapping helps simplify the creation and updating of standards, making the continuous improvement process straightforward and effective.

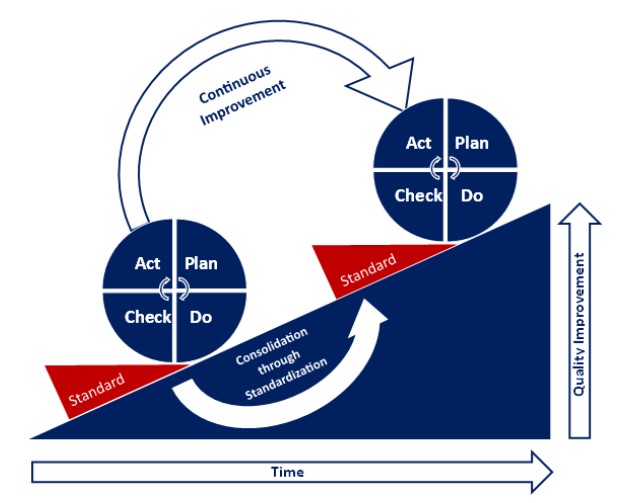

Enter the PDCA Cycle: Your Co-Pilot for Continuous Improvement

Let’s discuss the PDCA cycle - your co-pilot in the journey toward continuous improvement. This iterative four-step model serves as a roadmap for organizations to identify issues, set objectives, implement solutions, measure results, and refine processes, all while keeping a keen eye on data and evidence.

Here’s how it works:

Plan: Identify the root cause of a problem or opportunity, gather relevant data, and establish clear objectives and potential solutions.

Do: Test the solutions on a small scale to minimize disruption while gathering important data.

Check: Analyze the collected data to assess the effectiveness of the solution and determine if adjustments are needed.

Act: If the solution proves successful, standardize it. If it falls short, revisit the planning stage and refine your approach.

This ongoing cycle encourages a culture of continuous improvement.

Overcoming Analysis Paralysis

In the world of Lean, it’s important to remember that perfection is a moving target. We aim for practical results rather than an unattainable ideal. Beware of “Analysis Paralysis,” where the fear of making mistakes prevents timely decision-making.

Keep in mind that most decisions based on incremental improvements come with manageable risks and are often reversible. Don’t let fear ground your efforts - embrace the opportunity to make meaningful changes!

Conclusion

By implementing standardized work and the PDCA cycle, you’re setting aviation operations up for operational excellence. These practices will enhance efficiency, reduce waste, and foster a culture of continuous improvement.

So, are you ready to take your operational processes to the next level? Embrace standardized work and the PDCA cycle, and watch operations soar to new heights!