- Mar 4, 2025

The MRB Process Made Simple: Key Insights for Airworthiness Professionals

- David Lapesa Barrera

The Continuing Airworthiness of an aircraft begins with meeting the requirements established during its certification, followed by the minimum scheduled maintenance requirements necessary for developing an approved Aircraft Maintenance Program (AMP).

The Primary Sources for an AMP include the type design certification requirements - Airworthiness Limitations (ALS) and Certification Maintenance Requirements (CMR) - and the initial scheduled maintenance tasks outlined in the Maintenance Review Board Report (MRBR).

Here’s a breakdown of what you need to know about the MRBR process, its standards, and its role in the development of initial maintenance programs for newly certified aircraft and engines.

The MRB Process

So, who actually kicks off the MRB process? The MRB process begins with the application from the intended Type Certificate Holder (TCH), an approved design organization, and it primarily involves the certification authority of the aircraft's state of design, along with representatives from the aviation industry, including air operators. Additionally, regulatory authorities from the states of intended operation, other design organizations, and other interested parties may also participate in the process to ensure comprehensive review and compliance.

The standards for the MRB process at the highest level are outlined in the ICAO Airworthiness Manual Doc 9760. Following this manual, the International Maintenance Review Board Policy Board (IMRBPB) issues the International MRB Process Standard (IMPS), ensuring harmonization across certification bodies.

A key element of the MRB process is the use of the MSG-3 methodology, which is a task-oriented approach to determine maintenance tasks and intervals.

If you feel like you're drowning in acronyms—MRB, IMRBPB, MSG-3—you’re not alone! But don’t worry, each one plays a crucial role in ensuring aircraft stay airworthy. Let’s break them down.

The Role of the IMRBPB

The IMRBPB consists of aviation regulatory authorities and industry representatives. Its main objective is to develop procedures and guidance on the MRB process and the use of the MSG-3 methodology. The board meets annually to discuss and standardize the MRB process.

It includes members from major regulatory authorities, including Australia, Canada, the EU, the US, and more. Industry representatives from organizations like the MPIG (Maintenance Programs Industry Group) also play a key role. The IMRBPB's positions become policy only when are adopted by the corresponding regulatory authority.

The IMRBPB issues the International MRB Process Standard (IMPS) as guidance to standardize the processes and procedures to be used by the regulatory authorities in the oversight and approval of scheduled maintenance requirements.

The International MRB Process Standard (IMPS)

The IMPS, written in compliance with the ICAO MRB requirements, defines the detailed procedures for developing scheduled maintenance requirements for larger aircraft (over 15,000 kg). Although recommended for larger aircraft, the MRB process may be applied to smaller aircraft if the applicant chooses to do so.

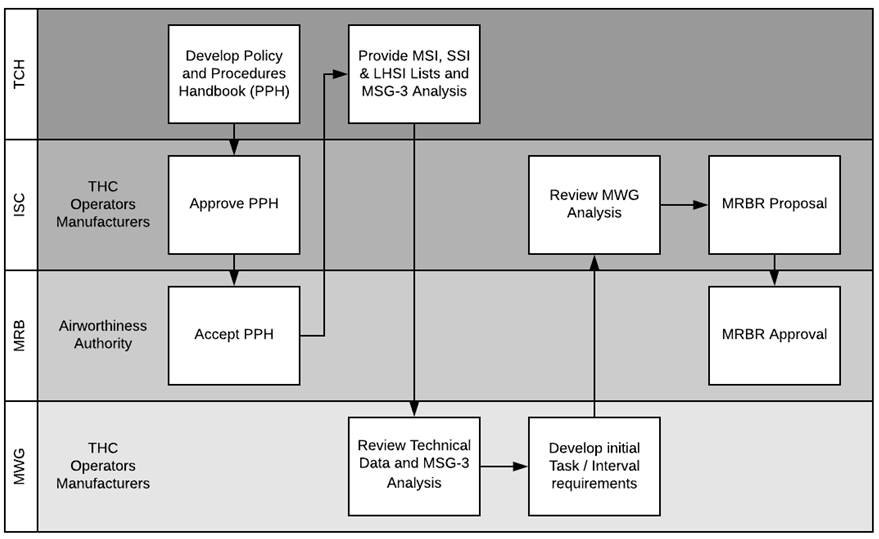

The MRBR is developed through collaboration between the Type Certificate Holder (TCH), the Certification Authority (CA), and other regulatory bodies. The MSG-3 methodology is used to propose maintenance tasks and intervals, which are reviewed by the Industry Steering Committee (ISC). Once finalized, the MRBR is submitted to the MRB for approval.

Interested in the full details? Access this standard document here.

Key Players in the MRB Process

The MRB process is carried out by various bodies, each with specific roles:

MRB (Maintenance Review Board): Responsible for approving the MRBR under the guidance of the MRB Chairperson. The MRB oversees the process, ensures proper training, and approves the final MRBR.

TCH (Type Certificate Holder): Applies for the MRB process and provides the necessary technical data. The TCH also develops the Policy and Procedures Handbook (PPH), which guides the working groups (WG) through the process.

ISC (Industry Steering Committee): This body manages the working groups, prepares the MRBR, and ensures all necessary technical and maintenance data is presented to the MRB for review.

MWG (Maintenance Working Groups): Specialists from various areas, including the applicant, operators and maintenance organizations, review the MSG-3 analysis and propose maintenance tasks and intervals based on technical data.

MRB Process. Source: Aircraft Maintenance Programs (Lapesa Barrera, 2022).

Operators play a key role in the Industry Steering Committee (ISC) and Maintenance Working Groups (MWG). This process isn’t just about collaboration—it’s about influencing decisions that directly impact operational efficiency and costs.

Note on Acronyms: Don't worry if acronyms like MSI (Maintenance Significant Item), SSI (Structural Significant Item), and LHSI (L/HIRF Significant Items) seem unclear right now - these are just items categorized based on their significance and potential safety impact, and we'll explain them in greater detail in our upcoming posts on the MSG-3 methodology.

The PPH (Policy and Procedures Handbook)

The PPH serves as the essential guide for developing the initial minimum scheduled maintenance and inspection requirements. It consolidates all relevant data, including the IMPS and MSG-3 standards, adapted to the specific aircraft project. Any deviations from the standard process must be approved by the competent authority and reflected in the PPH.

Utilization Considerations

The MSG-3 analysis as a whole assumes an anticipated average annual utilization of the aircraft. Task intervals are determined in function of this assumption and are valid for the defined utilization envelope.

The utilization envelope is reflected in the PPH and the MRBR. When the utilization falls out of the utilization envelope defined in the MRBR, the Type Certificate Holder is responsible for developing specific recommendations, such as Low Utilization Recommendations (LUR).

Want to dive deeper into MRBR and MSG-3 processes? Take your Aircraft Maintenance Program skills to the next level with The Lean Airline Academy.