- May 13, 2025

MSG-4: Leveraging Aircraft Health Monitoring for Condition-Based Maintenance

- David Lapesa Barrera

The transition from MSG-3 to MSG-4 will mark a crucial shift in aircraft maintenance practices, particularly with the integration of Aircraft Health Monitoring (AHM).

In the MSG-3 standard, AHM is limited to non-safety tasks, provided these tasks do not cover Candidate Certification Maintenance Requirements (CCMRs). While AHM can offer alternative procedures to classic maintenance tasks, a classic task selection is still required.

The recommendations for MSG-4, however, takes a more forward-thinking approach by enhancing existing MSG processes and workflows. Rather than treating AHM as a standalone analysis, MSG-4 proposes integrating AHM throughout the entire maintenance strategy. This shift aims to rethink the design of health monitoring systems, expanding their scope to support the full aircraft lifecycle. The goal is to eliminate the need for selecting classic tasks by integrating AHM as a form of Condition-Based Maintenance (CBM), enabling maintenance decisions to be driven by real-time data.

Maintenance Approaches

Maintenance can be broadly classified into reactive and proactive. Reactive maintenance, often called run-to-fail, involves fixing equipment only after it breaks. It can lead to unexpected downtime and higher repair costs.

Figure 1. Maintenance Approaches

Proactive maintenance, on the other hand, aims to prevent failures before they occur. It includes preventive maintenance, where tasks are scheduled at regular intervals based on time or usage, and Predictive, which relies on aircraft data to assess an asset's condition. Predictive maintenance can be either diagnostic (responding to detected issues) or prognostic (predicting failures in advance), allowing maintenance to be performed only when needed. This makes it more efficient and resource-effective, though it requires monitoring technology. Condition-Based Maintenance falls under the Proactive maintenance category.

Condition-Based Maintenance (CBM)

Condition-Based Maintenance (CBM) is a methodology that continuously monitors an asset’s condition to determine when maintenance is required. Unlike traditional time-based maintenance, CBM triggers maintenance actions only when performance indicators suggest a decline in functionality or signs of an impending failure. This approach is more efficient, as it allows maintenance to be performed only when necessary, reducing unnecessary work and ensuring resources are used effectively.

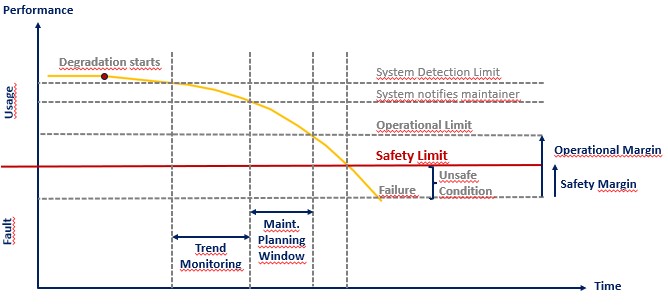

Figure 2. CBM for Systems

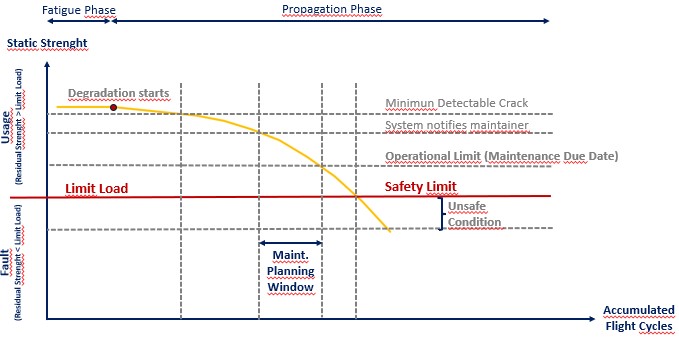

Figure 3. CBM for Structures

CBM does not always rely on real-time monitoring. In some cases, the condition data might be gathered periodically or through intervals based on specific needs, rather than continuously in real time. For example, certain indicators, such as an oil sample analysis, may be assessed only during scheduled inspections or when specific thresholds are met. This approach can sometimes delay the identification of issues until the next evaluation point.

To ensure MSG-4 is future-proof and ready for emerging technologies, it is recommended that a review be conducted to evaluate all possible CBM applications within the system. This review should aim to fully integrate emerging and future technologies into the workflow, ensuring that MSG-4 remains adaptable and capable of leveraging the latest innovations in aircraft health monitoring. By aligning with the future of aviation technology, MSG-4 can drive not only improved efficiency but also increased reliability and safety across the aircraft’s lifecycle.

Conclusion

The integration of Aircraft Health Monitoring (AHM) into MSG-4 represents a pivotal evolution in maintenance strategy, shifting from traditional scheduled tasks to more intelligent, data-driven decision-making, enabling Condition-Based Maintenance (CBM).

Stay tuned for our upcoming articles of The Lean Airworthiness Blog, where we’ll continue to explore the changes of the upcoming MSG-4 standard and what they mean for the industry.

And if you're ready to get ahead of the curve, don't miss our course: MSG-4: The Future of Aircraft Maintenance — designed to equip professionals with the knowledge and tools needed to lead in this new era.

Further Reading

Recommendations for the Development of MSG-4 – Airlines for America

Condition-Based Maintenance (CBM) in the Digital Transformation Stream – International Council of the Aeronautical Sciences, 32nd Congress

Condition Based Maintenance Plus (CBM+), Guidebook – U.S. Department of Defense

From Aircraft Health Monitoring to Aircraft Health Management – IATA White Paper on AHM